The regulation from the Department of Transportation (DOT) on conspicuity material, referred to as DOT C2, states that each trailer of 80 or more inches overall width, and with a GVWR over 10,000 lbs., must have retro-reflective sheeting, such as reflective tape. (trailer designation comes with some additional stipulations such as date of manufacturing, etc)

All vehicles sold in the United States have factory equipped and legally required devices helping them to be visible in low light and inclement weather. However, the objective is to increase safety records of large trucks by ensuring the location and size of the trailer is clearly seen. As we stated in our previous post “How to Increase Safety for Large Trucks with Conspicuity Tape”

“The word “conspicuity” means that which is very obvious to the eye (like something that is conspicuous from a distance). In this case, conspicuity refers to a truck being able to draw attention to its presence. All vehicles sold in the United States come factory equipped with certain legally-required devices helping them be conspicuous to some degree. However, the purpose of making a truck conspicuous is more than just enhancing its visibility. The real objective is to provide other drivers with information about the truck’s size, position and other aspects of its presence.”

It is very important to use tape that meets the stringent requirements of DOT. For instance, the DOT C2 regulation states that the retroreflective sheeting should be in a pattern of alternating white and red color segments. The stripes are to be 11” red and 7” white alternating stripes. Therefore, it is important to purchase conspicuity tape of the highest caliber, so, the tape merely needs to be applied in the appropriate place on the trailer without additional considerations.

Where to Install the C2 Reflective Tape

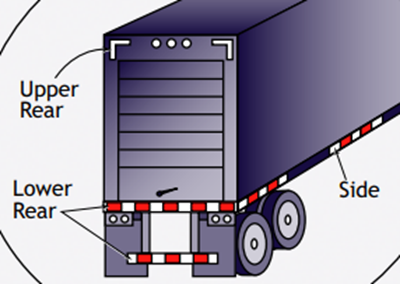

This reflective tape needs to be applied to the truck trailer in a certain manner to meet the DOT C2 regulations. The places on the trailer that need to have the tape applied are the sides and rear of each trailer and in white to the upper rear corners of each trailer. Retroreflective sheeting does not have to be applied to discontinuous surfaces such as outside ribs, stake post pickets on platform trailers, and external protruding beams, or to items of equipment such as door hinges and lamp bodies on trailers.

For example, regarding the rear of truck tractors, the tape should be applied to the rear of each truck tractor with two strips of sheeting in alternating colors, each not less than 600 mm long, located as close as practicable to the edges of the rear fenders, mudflaps, or the mudflap support brackets, to mark the width of the truck tractor. The strips shall be mounted as horizontal as practicable, in a vertical plane facing the rear, on the rear fenders, on the mudflap support brackets, on plates attached to the mudflap support brackets, or on the mudflaps. Strips on mudflaps shall be mounted not lower than 300 mm below the upper horizontal edge of the mudflap. There are exceptions if the vehicle is certified with temporary mudflap support brackets.

Regulations Regarding Tape Placement

For the complete and updated regulation, refer to S5.7.1.3 Sheeting pattern, dimensions, and relative coefficients of retroreflection.

“Location. (a) Retroreflective sheeting shall be applied to each trailer and truck tractor as specified below, but need not be applied to discontinuous surfaces such as outside ribs, stake post pickets on platform trailers, and external protruding beams, or to items of equipment such as door hinges and lamp bodies on trailers and body joints, stiffening beads, drip rails and rolled surfaces on truck tractors.(b) The edge of white sheeting shall not be located closer than 75 mm to the edge of the luminous lens area of any red or amber lamp that is required by this standard.(c) The edge of red sheeting shall not be located closer than 75 mm to the edge of the luminous lens area of any amber lamp that is required by this standard.

S5.7.1.4.1 Rear of trailers. Retroreflective sheeting shall be applied to the rear of each trailer as follows, except that Element 2 is not required for container chassis or for platform trailers without bulkheads, and Element 3 is not required for trailers without underride protection devices:(a) Element 1: A strip of sheeting, as horizontal as practicable, in alternating colors across the full width of the trailer, as close to the extreme edges as practicable, and as close as practicable to not less than 375 mm and not more than 1525 mm above the road surface at the stripe centerline with the trailer at curb weight.(b) Element 2: Two pairs of white strips of sheeting, each pair consisting of strips 300 mm long of grade DOT-C2, DOT-C3, or DOT-C4, applied horizontally and vertically to the right and left upper contours of the body, as viewed from the rear, as close to the top of the trailer and as far apart as practicable. If the perimeter of the body, as viewed from the rear, is other than rectangular, the strips may be applied along the perimeter, as close as practicable to the uppermost and outermost areas of the rear of the body on the left and right sides.(c) Element 3: A strip of sheeting in alternating colors across the full width of the horizontal member of the rear underride protection device. Grade DOT-C2 material not less than 38 mm wide may be used.

S5.7.1.4.2 Side of trailers. Retroreflective sheeting shall be applied to each side of a trailer as follows:(a) A strip of sheeting, as horizontal as practicable, in alternating colors, originating and terminating as close to the front and rear as practicable, as close as practicable to not less than 375 mm and not more than 1525 mm above the road surface at the stripe centerline with the trailer at curb weight, except that at the location chosen the strip shall not be obscured in whole or in part by other motor vehicle equipment or trailer cargo. The strip need not be continuous as long as not less than half of the length of the trailer is covered and the spaces are distributed as evenly as practicable.(b) If necessary to clear rivet heads or other similar obstructions, grade DOT-C2 retroreflective sheeting may be separated into two 25 mm wide strips of the same length and color, separated by a space of not more than 25 mm, and used in place of the retroreflective sheeting that would otherwise be applied.”

DOT Reflective C2 Tape Specifications

The Conspicuity Tape from Traffic Safety Direct meets the requirements mentioned above and more.

-

- 11” red and 7” white alternating stripes

- 2” x 50-yard roll

- Made from Diamond Grade reflective material that is 6 times brighter than conventional markings

- Reflect at angles approaching 90 degrees

- Rigid design with pressure sensitive adhesive for easy application

- Vivid red and bright white colors to ensure maximum reflectivity and daytime visibility

- Extremely durable and non-corroding formulation that resists dirt, elements, aging, and common solvents for years

- DOT certified

- Meets and exceeds NHTSA requirements

- 7-year limited warranty

Although this red and white reflective tape is a trucking industry staple, it is also an ideal added safety feature for Fire Trucks, EMS Vehicles, School Buses and anything that needs increased conspicuity.

Contact us to discuss the application and use of DOT Conspicuity tape. We are here to help.